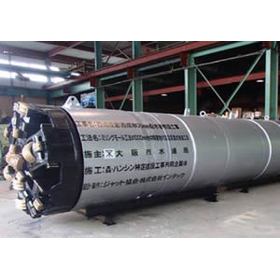

Milling Mall Construction Method Case Study: Ise Bay Crossing Gas Pipeline Installation Project

Immediately after departure, excavate the stone masonry wire cage and tetrapod section of about 20 meters!

The construction site for the Ise Bay Crossing Gas Pipeline installation encountered the discovery of old stone masonry (large boulders) in addition to results from prior magnetic surveys indicating some metal reactions, leading to the adoption of the milling mole method. During the excavation of the launch shaft, the stone masonry and tetrapods that were unearthed were significantly larger than the nominal diameter of φ1000mm, making cutting very difficult. The thrust pipes also utilized composite steel pipes with rolling prevention features specifically designed for milling. During construction, fragments of large boulders and wire were discovered, and it is believed that the metal reaction was due to this wire, which was likely associated with the large boulders contained in a wire cage. 【Construction Case】 ■ Project Name: Ise Bay Crossing Gas Pipeline Installation (Gas Conduit Construction) ■ Client: Toho Gas Co., Ltd. ■ Contractor: Kajima Corporation ■ Pipe Diameter: 1000 ■ Thrust Length: 68.47m ■ Soil Type: Riprap, Sandy Soil ■ N Value/Gravel Ratio/Maximum Gravel Diameter: N=50 G=80% φmax=1000mm ■ Construction Period: 2011.12.11 to 2012.2.8 (2 months) ■ Type of Obstacle: Wire, Tetrapod Old Stone Masonry (Large Boulders) *For more details, please refer to the PDF materials or feel free to contact us.

- Company:ヤスダエンジニアリング

- Price:Other

![[Milling Mall Construction Method Case Study] Kishiwada City](https://image.www.ipros.com/public/product/image/089/2000367631/IPROS5589357986667498783.jpg?w=280&h=280)

![[Milling Mall Method Construction Case] New Tunnel Construction for the 2-1 Planning Route in the Temachi Area](https://image.www.ipros.com/public/product/image/0d1/2000367699/IPROS1908266368131029686.jpg?w=280&h=280)

![[Video Available] Measures against abnormal weather, guerrilla rainstorms, and rainwater!](https://image.www.ipros.com/public/product/image/cc1/2000429532/IPROS18358409666108027113.png?w=280&h=280)